OUR PROCESS

Innovative Production Machinery is not just a tag line it’s our passion, we deliver what we claim.

Simple Solutions for your Complex Problems

You speak directly to the team members who create your equipment at both the pre- and post-install levels. There is no outsourcing here. Our in-house capabilities at our state-of-the-art central Virginia facility allow us to have oversight of your entire custom automation project.

Typical lead time for build is 12 weeks to 24 months, depending on the complexity of the project. We start with the end in mind, listen to your input to innovate a solution, and involve you throughout the process.

- Our staff visit your site to understand your operation, gather project specifications, and discuss your automation goals

- Our team of mechanical and electrical engineers join forces on a design proposal

- AIT team meets with you to review the design concept and proposal

- Receipt of signed proposal and your initial payment allows us to schedule your project

Our goal is a seamless hand-off. We support you through installation and operator training at your facility.

INNOVATION

We don’t get fixated on one solution for your project. Rather we consider several options to reduce waste and simplify processes for end users. We believe the only way to deliver you an optimized machine is to test, refine, fabricate, and document until the project goals are met.

We are collaborators. We start by working with you to define your project requirements and help develop for specifics about production cycle time, cleanliness requirements, operator involvement, user interface safety, and production rates.

To us, innovation means meeting or exceeding process and cycle times, accuracy tolerances, and quality standards by applying our prior success and collective experience to your project.

ENGINEERING

Our staff includes engineers who specialize in mechanical design, manufacturing, electrical design, industrial controls, and PLC programming, and project engineering and management. Our team is all focused on producing the optimal machine design, control system, material handling, assembly, and testing processes for your project.

From this information, innovation and problem-solving begins. Our team will explore materials and methods best suited to your environment and develop practical concepts that we refine into effective solutions to execute your machine design, control system design, and write and test the process control software.

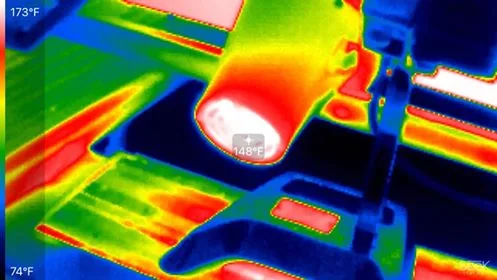

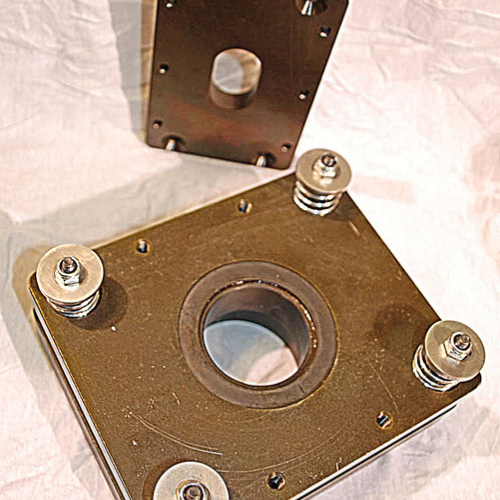

MANUFACTURING

Your automation solution is built and tested in our manufacturing department staffed by machinists, welders, and electro-mechanical assemblers with decades of experience. Each component is inspected to assure it has met the specifications of the design.

SHIPPING, PARTS, AND SERVICE

We service and support all of the equipment we build from pre-installation information for layout, power, and compressed air to shipping from our facility to yours. Phone support after installation or contracted on-site service for your machine is also available. Spare parts can be requested via email to parts@autoindtech.com.

Contact Us

Hours of Operation

MON-FRI 8AM to 4:30PM

Phone

(434) 525-2292

Spare Parts

parts@autoindtech.com

More Info

info@autoindtech.com